The majority of today’s engines have a four-stroke design that uses three fluids: air-fuel fuel, water / glycol coolant, and engine oil. These fluids can never come into contact with each other. To ensure these fluids are routed correctly between components without mixing, there is the head gasket.

What is a Cylinder Head Gasket?

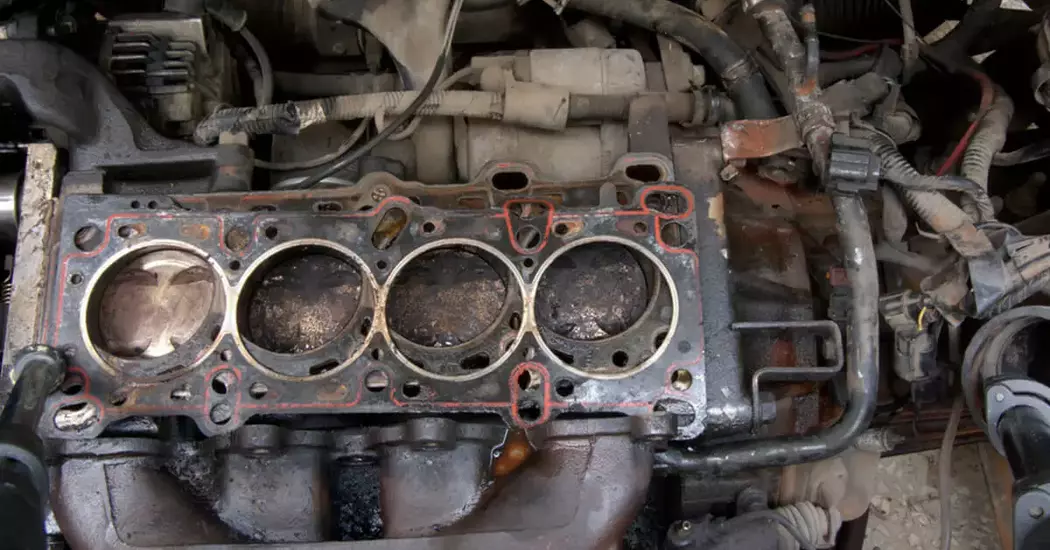

Let’s start by talking about what a cylinder head gasket is. The cylinder head gasket exists between your engine block and the cylinder head. Every modern car has this seal but their thickness and construction vary depending on the engine design by the manufacturer. The cylinder head gasket is so important because it seals the combustion chamber, which allows your car to create the right compression and contain the exhaust gases, which helps to maintain the efficiency of your engine. The cylinder head gasket also keeps coolant and oil out of the combustion chamber, which is important for the same reasons you wouldn’t want coolant or oil to leak elsewhere.

Now that we know what a cylinder head gasket is, it is important to learn what are the symptoms of cylinder head gasket failure look like to avoid higher expense due to additional engine damage caused by driving with a gasket. toasted cylinder head. To understand the symptoms, it can be helpful to understand why a cylinder head gasket can fail.

Why do Cylinder Head Gaskets Break?

The cylinder head gasket creates a seal between the engine block and the cylinder head. This means that your cylinder head gasket must seal both extremely hot and high pressure combustion gases as well as engine coolant, which can range from cold ambient temperatures to your engine’s normal operating temperature. Because of the wide temperature range and the relatively large surface area, it is not uncommon for cylinder head gaskets to develop leaks over time. This can happen regardless of the make or model of your car or the type of head gasket used.

As the head gasket seals the passage of coolant from the atmosphere and the combustion chamber, you can not see much of the head gasket on a vehicle with the engine installed. Because much of the gasket can not be seen without disassembling the engine, symptoms of broken cylinder head gaskets can be very difficult to diagnose. Since a visual inspection will usually not prove a cylinder head gasket leak, it is important to know the other symptoms so that you can accurately diagnose a cylinder head gasket problem.

Types of Cylinder Head Gaskets

Understanding the different types of cylinder head gaskets can help you choose the right one for your vehicle or better understand your engine’s needs. Here’s a breakdown of the common types:

1. Multi-Layer Steel (MLS) Gaskets

MLS gaskets are made of multiple layers of steel and elastomer. They’re designed to handle high-pressure and high-temperature environments, making them ideal for modern engines. They offer excellent durability and are less likely to blow under stress compared to other gasket types.

2. Copper Gaskets

Copper gaskets are known for their excellent thermal conductivity and durability. They can handle extreme heat and pressure, making them a popular choice for high-performance and racing engines. However, they require a perfect fit and surface finish to seal properly, which can make them more challenging to install.

3. Composite Gaskets

Composite gaskets are made from a combination of materials, including graphite and asbestos (in older models). They’re generally more affordable and easier to install than MLS or copper gaskets. However, they may not be as durable under extreme conditions, making them better suited for everyday driving.

4. Overview of Different Gasket Materials and Their Specific Uses

Each gasket material has its strengths and ideal applications. MLS gaskets are perfect for high-performance engines, copper gaskets excel in extreme heat, and composite gaskets are great for standard engines. Understanding these differences helps in selecting the right gasket for your vehicle’s needs.

What Are the Signs and Symptoms of A Blown Head Gasket?

A driver might often wonder what causes a blown head gasket. The truth is, everything from the cooling system to the combustion chamber could be to blame. Most confusing is the fact that symptoms that resemble those of a cylinder head gasket failure will sometimes come from other causes. In some cases, a symptom may appear due to multiple failures in the engine. Examples might include the following reason: Overheating can be caused by a restricted radiator, which can get worse as you ride. The coolant in the oil, typically blamed on the cylinder head gaskets, could actually be due to issues with the intake gasket.

Such symptoms may or may not be due to the cylinder head gasket. An accurate diagnosis often depends on the expertise of a qualified technician. How do you know if a cylinder head gasket is burnt out?

- Coolant leaks outside the underside of the exhaust manifold

- White smoke from the exhaust pipe

- Bubbles in the radiator or coolant reservoir

- Motor overheated

- White milky oil

- Dirty spark plugs

- Poor integrity of the cooling system

1. Leaking external cylinder head gasket

A leaking cylinder head gasket on the outside would cause coolant to come from below the intake or exhaust manifold and often only occurs when the engine is fully warmed up. If there are no other cooling passages or hoses near the cylinder head gasket, you may be able to identify the leak as a cylinder head gasket leak, but if there are other cooling passages Nearby, you may need to add UV dye to the coolant and then look at the cylinder head gaskets with UV light to positively identify the leak.

2. White smoke from the exhaust pipe

Most cylinder head gasket leaks are internal to the engine, allowing coolant to flow into the combustion chamber on each stroke of the intake. When this happens, the coolant evaporates with the combustion process and appears as white smoke from the exhaust pipe. This smoke can be differentiated from humidity during a cold start by a sweet smell and will continue even when the engine is hot. If the leak in the head gasket is large, this white smoke can often be excessive and escape from the exhaust pipe.

3. Bubbles in the radiator

In addition to allowing coolant to enter the combustion chamber, an internal cylinder head gasket leak allows exhaust gases to enter the coolant. This can cause bubbles in the radiator or coolant reservoir, making the coolant appear to be boiling even when it is cold. Bubbles are exhaust gases that enter the cooling system during the combustion process.

4. Motor overheated

If you have a blown head gasket, your engine will usually overheat after long trips. It happens both due to the lack of coolant as your engine consumes it, but also the efficient combustion process, excessive heat from the exhaust into the coolant, and the inability of your radiator. vehicle to cool dirty coolant. If your engine overheats, it can cause a lot of problems. The biggest concern is the expansion of metal components beyond what they were designed for, which can cause cracking and warping. Additionally, it can permanently damage the seals and cause further leaks in your engine.

5. White or milky oil

When coolant seeps into your combustion chamber, it seeps past your piston rings into your oil. Over time, the oil and water will mix together and turn the oil milky white. You can look for it on your dipstick and around your engine oil cap. Having water in your oil will make your oil ineffective at properly lubricating your engine, which will quickly wear down your cylinder walls and crank and camshaft bearings. Even if you do not drive the vehicle, the presence of water in the oil can cause rusting on machined surfaces, which can lead to punctures in the metal and require an engine rebuild.

6. Dirty spark plug

As the coolant burns in your combustion chamber, it will leave tiny white deposits on your spark plug typically around the ground strap and electrode. Other issues can cause these white deposits, so this is not a conclusive symptom of the broken head seal, but if others are present it could give you more evidence.

7. Poor integrity of the cooling system

If your head gasket leaks, pressurizing your cooling system and monitoring the pressure loss can also prove that you have a broken head gasket. Since there might be other leaks that you don’t know about, this is also not a conclusive test, but again more indications that you might have a blown head gasket. Likewise, you can perform a leak test which pressurizes the combustion chamber with compressed air and measures the amount of air that escapes through the head gasket or other opening in the combustion chamber.

Can I Drive with A Blown Head Gasket?

If you have multiple symptoms of a blown cylinder head gasket, it is important to drive your vehicle as little as possible. Hot gases and cold coolant moving through the hole in the gasket can quickly erode or warp the metal cylinder head or engine block, leaving you with expensive machining bills or even having to purchase new cylinder heads or a new engine. Also, having water in your engine oil can destroy your bearings quickly.

How to Prevent Head Gasket Failure

To minimize the risk of cylinder head gasket failure in your vehicle, perform the following steps accordingly:

- Before the coolant drops below a pH of 7.0, fill the reservoir.

- Use ready-made water / coolant mixtures – never add the two separately.

- Stop the engine when it overheats.

- Examine and remedy overheating conditions. Have the engine diagnosed by a professional if necessary.

There are several ways to reduce your risk of breaking a cylinder head gasket. The first is to keep the combustion chamber pressures as low as possible. If your vehicle is supercharged, make sure your boost level is set to the factory setting to keep combustion pressures under control. Also, make sure your engine does not have ignition or knocking due to too advanced timing or carbon buildup.

Likewise, maintaining low engine speeds will reduce stress and heat on your cylinder head gasket, so avoid running your engine at high rpm. Finally, if your car has a manual transmission, avoid downshifting to slow the car down.

If you are rebuilding an engine, you can reduce the risk of a blown head gasket in the future by using properly lubricated and tightened head studs in the proper order for the correct torque setting.

You can also make sure that your cylinder head mating surface is properly prepared for the new gasket. Likewise, using a multi-layer steel or other metal cylinder head gasket can improve the reliability of your engine.

These are just a few different steps you can take to prevent head gasket failure, but sometimes, even by following these steps, you can still end up with a blown head gasket. If not taken care of immediately, blown head gaskets can turn into bigger engine problems that will end up being even more expensive to repair.

Common Myths About Head Gasket Failures

There are several myths surrounding head gasket failures. Let’s clear up some common misconceptions:

- “Head Gaskets Only Fail Due to Overheating”

While overheating is a common cause, head gaskets can fail due to poor installation, manufacturing defects, or even prolonged exposure to harsh driving conditions. - “A Blown Head Gasket Means the End of Your Engine”

Not necessarily. If caught early, a blown head gasket can be repaired, and your engine can continue to run well. However, ignoring the issue can lead to more severe damage. - “Using a Head Gasket Sealer is a Permanent Fix”

Head gasket sealers can be a temporary solution, but they shouldn’t replace a proper repair. They may help in emergencies, but for long-term reliability, it’s best to replace the gasket.

Cost and Time Estimates for Head Gasket Repairs

Repairing a blown head gasket can be a significant investment. Here’s what you need to know:

1. Factors Influencing Repair Costs

The cost of repairing a head gasket can vary depending on several factors, including the make and model of your vehicle, the extent of the damage, and the labor rates in your area. Additionally, if other components are damaged, such as the cylinder head, the cost can increase significantly.

2. Estimated Time for Repair

The time required to replace a head gasket can also vary. It generally takes between 8 to 12 hours of labor, depending on the complexity of the engine. This means that your vehicle may be in the shop for a day or more, especially if additional work is needed.

3. Information on the Financial and Time Investment Required for Fixing a Blown Head Gasket

While repairing a head gasket can be costly, it’s often necessary to prevent further engine damage. It’s essential to weigh the costs and benefits and consider the long-term health of your vehicle when deciding on repairs.

When to Seek Professional Help

Knowing when to consult a professional can save you from more significant issues down the road:

1. Signs That Indicate It’s Time to Consult a Professional Mechanic

If you notice symptoms like white smoke from the exhaust, overheating, or coolant and oil mixing, it’s time to see a mechanic. These signs indicate potential head gasket issues that require professional diagnosis and repair.

2. Benefits of Professional Diagnosis and Repair

Professional mechanics have the tools and expertise to accurately diagnose and fix head gasket problems. They can also check for other related issues, ensuring a comprehensive solution. While DIY repairs are possible, professional work ensures the job is done correctly and safely, providing peace of mind and protecting your engine from further damage.

How to Test a Blown Head Gasket

A reliable way to determine if a cylinder head gasket is burnt out is to test with carbon dioxide. In this test, the coolant is examined for traces of flue gas. The test is performed with a device that uses a solution that changes color on contact with carbon monoxide. The steps are as follows:

- Lower the coolant level in the radiator (to provide test air space).

- Warm up the engine (for improved accuracy).

- Use the tool to extract the smoke samples from the coolant.

- Mix the samples in the test solution.

If the solution turns yellow, the coolant has failed the test, indicating a problem. True, the test does not always work, and carbon dioxide can still be present in the coolant without changing the color of the solution. Nevertheless, the test is generally reliable in detecting a problem that is symptomatic of an unhealthy engine. Another problem that a carbon dioxide test could possibly reveal is a ruptured cylinder head, which causes symptoms similar to a faulty cylinder head gasket.

In many cases, a cylinder head crack will be too small for the human eye to spot, but it could still be a major problem. In some repair shops, cracks are found with the use of dyes or the application of pressure tests. As with coolant testing, cylinder head testing is best performed by a professional automotive technician.

READ ALSO : All About Pcv Valves: Bad PCV valve Symptoms, Testing Methods, And The Most Asked Q/As

TEQsxXtvIbkSjM

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/ka-GE/register?ref=RQUR4BEO

I genuinely enjoy reading through on this site, it has fantastic blog posts. “Beware lest in your anxiety to avoid war you obtain a master.” by Demosthenes.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I’m curious to find out what blog system you have been utilizing? I’m having some minor security problems with my latest website and I’d like to find something more secure. Do you have any recommendations?

Yeah bookmaking this wasn’t a speculative determination outstanding post! .

Regards for helping out, fantastic info. “Job dissatisfaction is the number one factor in whether you survive your first heart attack.” by Anthony Robbins.

iwinclub – Noi quy tu dang cap cua gioi thuong luu, la mot trong nhung cong game bai doi thuong uy tin nhat hien nay tai thi truong Chau A. cffresearch.org

What¦s Going down i’m new to this, I stumbled upon this I’ve found It positively helpful and it has aided me out loads. I hope to contribute & help different users like its aided me. Good job.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

IWIN là một sòng bạc thượng lưu chuyên đánh bài ăn tiền thật xanh chín Châu Á, iwin club cung cấp nhiều sản phẩm cá cược trực tuyến online uy tín chất lượng như: bắn cá, đá gà, game bài, nổ hũ, lô đề, cá độ thể thao. Đặc biệt tham gia iwin nhận code khuyến mãi liên tục được cổng game phát hằng tuần

Tải 789club để tham gia vào sân chơi giải trí uy tín với hàng trăm trò chơi đổi thưởng hấp dẫn. Từ bắn cá, slot game đến game bài, 789club đều mang lại trải nghiệm thú vị và cơ hội thắng lớn cho người chơi.

Game đổi thưởng uy tín luôn ưu tiên bảo mật thông tin người chơi và tốc độ thanh toán. Với các trò chơi hấp dẫn như Bầu cua tôm cá hay Tài xỉu, bạn có thể vừa thư giãn vừa tích lũy thêm thu nhập. Lựa chọn cổng game chất lượng sẽ mang lại trải nghiệm tuyệt vời.

An fascinating dialogue is worth comment. I think that you must write extra on this subject, it won’t be a taboo topic however typically individuals are not sufficient to talk on such topics. To the next. Cheers

Howdy just wanted to give you a quick heads up. The text in your post seem to be running off the screen in Chrome. I’m not sure if this is a formatting issue or something to do with web browser compatibility but I thought I’d post to let you know. The design and style look great though! Hope you get the issue solved soon. Cheers

It’s really a nice and useful piece of info. I am glad that you shared this helpful info with us. Please keep us up to date like this. Thank you for sharing.

great post, very informative. I wonder why the other specialists of this sector don’t notice this. You should continue your writing. I am sure, you’ve a huge readers’ base already!

Awsome info and right to the point. I don’t know if this is actually the best place to ask but do you people have any ideea where to hire some professional writers? Thanks 🙂

What i do not realize is in fact how you are not actually a lot more neatly-appreciated than you might be now. You are so intelligent. You understand thus considerably relating to this subject, made me personally consider it from a lot of various angles. Its like men and women don’t seem to be involved unless it’s something to do with Lady gaga! Your own stuffs excellent. All the time take care of it up!

Hi, I think your blog might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, awesome blog!

I see something genuinely special in this web site.

At this time it sounds like BlogEngine is the top blogging platform available right now. (from what I’ve read) Is that what you are using on your blog?

Thanks for any other informative web site. Where else could I get that type of information written in such an ideal means? I’ve a project that I am simply now running on, and I have been at the glance out for such info.

Thank you for every other excellent article. Where else could anyone get that type of info in such an ideal way of writing? I have a presentation subsequent week, and I’m at the search for such info.

You are my inspiration , I possess few blogs and rarely run out from to post .

My developer is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the costs. Buut he’s tryiong none the less.

I’ve beenn using WordPress on a variety oof

websites for about a year and am worried about switching to another platform.

I have heard fantastic things about blogengine.net.

Is there a way I can import all my wordpress posts int it?

Any help would be greatly appreciated! https://menbehealth.wordpress.com/

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:ремонт крупногабаритной техники в москве

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Профессиональный сервисный центр по ремонту техники в Перми.

Мы предлагаем: Ремонт гироскутеров Digma стоимость

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Hi, just required you to know I he added your site to my Google bookmarks due to your layout. But seriously, I believe your internet site has 1 in the freshest theme I??ve came across. It extremely helps make reading your blog significantly easier.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт холодильников gorenje цены, можете посмотреть на сайте: ремонт холодильников gorenje сервис

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

When I originally commented I clicked the -Notify me when new comments are added- checkbox and now each time a comment is added I get four emails with the same comment. Is there any way you can remove me from that service? Thanks!

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт кофемашин philips в москве, можете посмотреть на сайте: ремонт кофемашин philips цены

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Definitely, what a great blog and instructive posts, I surely will bookmark your website.Best Regards!